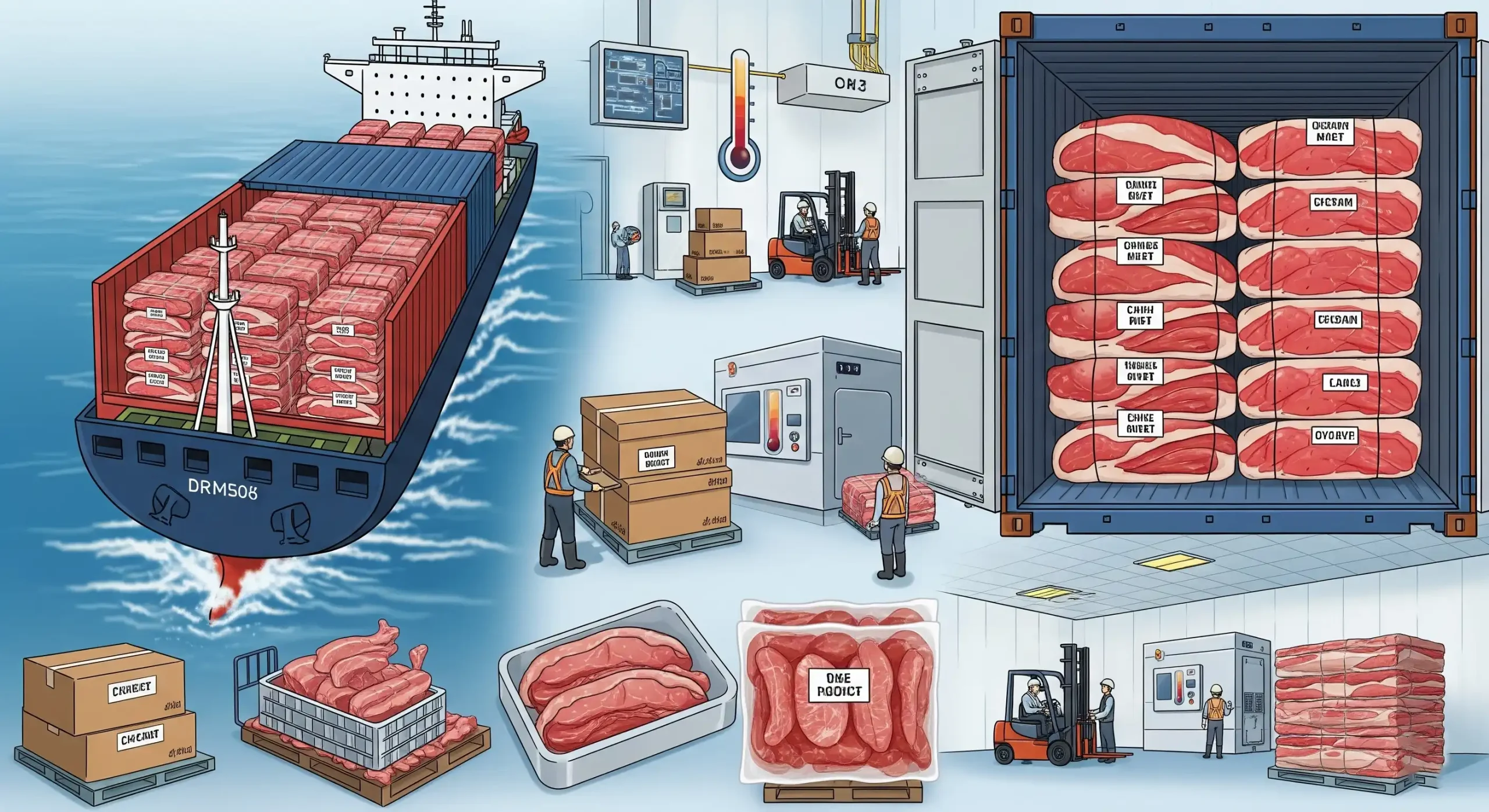

Importing frozen meat from various countries is one of the ways many countries, including Iran, meet their protein needs. However, the proper transportation and storage of this sensitive product are of utmost importance for public health, product quality, and consumer trust. In this article, you will learn step-by-step about the most important principles of hygienic transportation, storage, and maintenance of imported frozen meat.

Importance of Observing Hygienic Principles in Frozen Meat Transportation

Adhering to hygienic requirements in the transportation of frozen meat is essential not only for preserving the product’s physical quality but also for preventing the growth of pathogenic microorganisms. Due to its high moisture content and nutrient density, frozen meat provides a suitable environment for bacterial growth if not stored correctly.

Main reasons to prioritize hygiene in meat transportation:

- Prevention of microbial contamination: Even minor temperature fluctuations can reactivate dormant bacteria.

- Preservation of nutritional value: Unstable temperatures can lead to the deterioration of meat tissues and fat oxidation.

- Maintaining consumer trust and the importer’s brand reputation.

- Avoiding economic losses due to spoilage.

According to the Veterinary Organization’s guidelines, every imported consignment must be kept at a temperature below -18°C throughout the entire transportation route.

International Standards for Imported Frozen Meat

The import of frozen meat is subject to global regulations and standards that ensure the quality and safety of the product, regardless of its origin. Some of the most important standards include:

- HACCP (Hazard Analysis and Critical Control Points) A preventive system for identifying, assessing, and controlling health hazards. Meat importers are obliged to provide documentation related to the implementation of this standard.

- Codex Alimentarius International guidelines developed by FAO and WHO, focusing on aspects such as hygiene, packaging, labeling, and transportation conditions.

- ISO 22000 A food safety management system that focuses on supply chain processes from production to consumption.

- Destination Country Standards For example, in addition to international regulations, Iran has specific rules for meat imports set by the Veterinary Organization, the Ministry of Health, and Customs.

Failure to comply with any of these requirements may result in the consignment being stopped at entry points or condemned.

What is the Cold Chain and Why Is It Important?

The cold chain is an interconnected system of equipment, technology, and processes that maintains products like frozen meat at a specified temperature from the moment of production until consumption.

Main components of the cold chain:

- Primary cold storage in the country of origin.

- Refrigerated containers for sea or land transport.

- Customs cold storage and temporary warehouses.

- Refrigerated domestic transport to the distribution destination.

- Sales points with industrial freezers.

Importance of the cold chain in meat imports:

- Prevention of temperature fluctuations.

- Preservation of cellular structure and meat texture.

- Reduction of re-contamination probability.

- Extension of frozen meat shelf life.

Any break in this chain (e.g., power outage or open container door) can lead to rapid product spoilage.

Optimal Transportation Conditions for Imported Frozen Meat

The transportation of imported frozen meat requires strict adherence to technical, regulatory, and hygienic conditions.

Essential features for meat transportation:

- Constant temperature below -18°C.

- Refrigerated container with an automatic alarm system.

- Temperature recording system (Data Logger).

- Uniform air distribution and prevention of ventilation blockage.

- No excessive stacking of consignments.

Safe loading and unloading procedures at entry points: Loading must take place in fully hygienic cold storage facilities, and meat should be placed in durable, officially labeled packaging. At docks or airports, specialized refrigerated forklifts or cold corridors are used during unloading.

Monitoring temperature systems in transit: All containers must be equipped with data loggers with memory that record the temperature throughout the journey and send alerts in case of temperature fluctuations. This data can be reviewed upon the goods’ arrival at customs.

Storage Conditions for Frozen Meat in Warehouses

After entering the country, imported frozen meat must be stored in warehouses that meet specific standards.

Suitable warehouse environmental conditions:

- Constant temperature between -18°C and -25°C.

- Walls and floor with moisture and heat resistant insulation.

- Product not placed near doors or heat sources.

- Continuous and uniform airflow throughout the storage space.

- Power outage or temperature fluctuation alarm devices.

Required equipment in meat storage warehouses:

- Fixed or mobile industrial cold storage.

- Emergency power generator.

- Central data logger connected to the supervising operator.

- Visual identification tools and RFID for consignment tracking.

Permitted Storage Duration for Various Types of Frozen Meat

The storage duration for frozen meat depends on the type of meat, packaging conditions, initial freezing method, and storage temperature. International and national standards define specific ranges for each type of meat, as follows:

In large warehouses, FIFO (First-In, First-Out) systems are used to ensure that meat is consumed or distributed based on its arrival date, not just volume.

Key Points for Labeling Imported Meat

Accurate and standardized labeling is one of the most crucial steps for transparency in meat imports and plays a key role in building consumer trust.

Essential information on imported frozen meat labels:

- Country of origin.

- Name of the factory or producing brand.

- Production and freezing date.

- Expiration date.

- Trace Code.

- Net and gross weight.

- Type of meat and specifications (minced, boneless, fillet, leg, etc.).

- Approval from the country of origin’s Veterinary Organization.

- Import permit number.

Some labels include a QR Code for quick scanning of information in monitoring systems.

Quality Control and Hygienic Inspection of Imported Meat

All imported frozen meat consignments are subject to direct supervision by the Veterinary Organization of the Islamic Republic of Iran before entering the market.

Stages of hygienic inspection:

- Inspection of consignment documents: Including health certificate, transport certificate, initial freezing form.

- Physical inspection at customs: Observing container temperature, packaging integrity.

- Laboratory sampling: Checking for microorganisms, drug residues, parasitic contamination.

- Issuance of a hygienic clearance permit.

If tests yield unacceptable results, the goods are condemned or returned. The list of authorized countries for import is regularly updated and publicly announced by the Veterinary Organization.

Common Challenges in Transportation and Storage of Frozen Meat

The process of importing, transporting, and storing frozen meat can face numerous problems that directly affect the product’s safety and quality.

Key challenges:

- Power outages during transport or in warehouses.

- Delays in customs clearance and prolonged stay at the dock.

- Frequent opening and closing of container or cold room doors.

- Insufficient training of warehouse staff.

- Use of old equipment or equipment without standard certificates.

To counter these challenges, continuous monitoring, alarm technologies, and equipment modernization are necessary.

Suggested Solutions for Preserving Meat Quality

To prevent resource waste, reduce health risks, and maintain the importer’s brand reputation, implementing several practical solutions is recommended:

- Specialized training for cold storage and warehouse operators.

- Use of automatic emergency power generators.

- Installation of temperature alarm sensors connected to mobile or online monitoring.

- Storing products on pallets with sufficient spacing for better ventilation.

- Regular checking of compressor performance and refrigeration equipment.

- Regular evaluation of the supply chain from origin to retail.

The Role of Technology in Improving Transportation and Storage Processes

Modern technologies can revolutionize the process of storing imported frozen meat.

Useful technologies in this field:

- Internet of Things (IoT): For real-time recording and transmission of temperature, humidity, and compartment conditions.

- Blockchain: For transparent and unchangeable recording of transport records and temperature of each consignment.

- Cold chain tracking software: Real-time management and alerts for officials.

- Remote control systems: Automatic temperature adjustment and equipment performance checks, even from miles away.

These technologies can significantly reduce losses and increase satisfaction among health supervisors and customers.

Review of Importers’ Responsibilities in Maintaining the Cold Chain

Importers play a crucial role in ensuring the safety and quality of imported frozen meat. Commitment to legal and hygienic requirements is not only a legal obligation but also a condition for brand survival in today’s competitive market.

Key importer responsibilities:

- Selecting a reputable supplier: Factories that comply with international standards such as HACCP and ISO 22000.

- Supervising packaging at the origin: Durable, vacuum-sealed, and hygienically approved packaging.

- Complete documentation of the transport route: Data logger reports, transport certificates, official veterinary permits from the country of origin.

- Hiring technical experts at entry points: For visual and supervisory inspection of consignments at the dock or airport.

- Supervising contracted warehouses: Regular visits and receiving performance reports from cold storage facilities.

An importer’s disregard for these points may lead to the consignment’s condemnation or a ban on future activities.

The Role of Government and Regulatory Organizations in Imported Meat Safety

Iranian regulatory organizations play a vital role in controlling the quality of imported frozen meat.

Most important related bodies:

- Veterinary Organization of the Islamic Republic of Iran: Full hygienic supervision over animal consignments and granting clearance permits.

- Food and Drug Organization: Reviewing the quality of imported products in the field of public health.

- Customs of the Islamic Republic of Iran: Coordinating for rapid and correct clearance of inspected goods.

- Ministry of Agriculture Jihad: Regulating the import of livestock and animal products.

These organizations, through joint coordination and the use of digital systems, have made the monitoring process more efficient.

Final Recommendations for Imported Frozen Meat Industry Stakeholders

- Include a temperature maintenance guarantee in contracts.

- Utilize temperature alarm technology to react before a crisis occurs.

- Provide specialized training for all transport and warehouse staff.

- Initially import new consignments on a trial basis and conduct quality checks.

- Avoid collaborating with unknown brands without health certificates.

Suggested Resources for Further Reading

For more scientific and specialized information on the transportation and storage of frozen meat, you can refer to the following resources:

- FAO – Cold Chain Development

- Codex Alimentarius Commission

- Iran Veterinary Organization

- Iranian National Research Center for Animal Products

Imported frozen meat, if transported and stored under precise hygienic conditions, modern technology, and principled supervision, can be a healthy, economical, and reliable protein source for the community. The main responsibility for preserving the quality of this product lies with the importer, transporter, warehouse keeper, and health supervisor. Thanks to technological advancements and the development of health guidelines, risks can be minimized, and public health guaranteed.

Frequently Asked Questions about Imported Frozen Meat (FAQ)

- Is the quality of imported frozen meat lower than fresh domestic meat? No. If standards are met, the quality of frozen meat can be equal to or even higher than fresh meat.

- Does freezing kill microbes? Freezing inactivates some microbes but does not destroy them; hence, proper storage is crucial.

- If the cold storage power is cut for a few hours, will the meat spoil? If the temperature rises above -12°C, the cold chain is broken, and the meat may be damaged. It should be immediately inspected and tested.

- Is consuming frozen meat harmful to health? No, as long as the cold chain is maintained and the product is imported from reputable countries and brands.

- How can I verify the authenticity of imported meat? By scanning the trace code on the product label or through the Veterinary Organization’s monitoring systems.

- Can frozen meat be refrozen? Absolutely not. Thawing and refreezing lead to microbial growth and changes in meat taste and quality.

Conclusion: Ensuring Quality at Every Stage

The import, transportation, and storage of frozen meat is a complex, multi-stage process that requires precision, technical knowledge, and the use of up-to-date global standards. Adhering to cold chain principles, continuous monitoring of temperature conditions, staff training, and the use of new technologies can guarantee product quality and enhance food safety for the community. To achieve a high level of confidence and safety, every detail must be attended to, from the point of production until the product reaches the consumer.